Sponsored By

As research into hydrogen fuel cell vehicles intensifies, it is critical to acknowledge the challenge of developing safe, reliable fuel cells — a challenge presented by hydrogen itself.

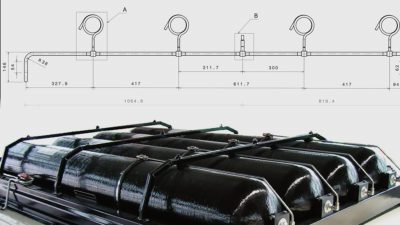

Being a small-molecule gas, hydrogen can leak through even the smallest of crevices and then be absorbed into the surrounding materials. In hydrogen-powered vehicles, more than 700 bar of pressure is required to keep the necessary energy density in the cells (Figure 1). When hydrogen is stored at refueling stations, the quick thermal and pressure changes can affect system integrity as the gas is released and decompresses. No leaks are permitted in either application.

Image: Swagelok

Figure 1. Hydrogen vehicle fuel delivery systems store the gas at pressures in excess of 700 bar to achieve the necessary energy density.

That is why the fittings in hydrogen applications, particularly those that connect the most critical parts of high-pressure hydrogen fuel systems, must be capable of delivering high levels of performance and reliability. Today, specialized options are available to contribute to those heightened performance demands. In this article, we will examine what those new fitting options look like in comparison to traditional cone and thread fittings and also highlight some specific design characteristics that make the new options ideal for hydrogen applications.

Seal Tightness

Since hydrogen can escape through the smallest of openings, seal tightness and leak resistance are two of the most important characteristics in fitting design and selection.

Traditionally, tube connections have a single line of sealing contact on a narrow surface between the tubing and fitting, which works well for most liquids and some gases. However, hydrogen has specific characteristics that make such connections more tenuous. Single-line seals are also vulnerable to vibration damage.

Hydrogen containment requires designs that include two lines of contact across longer sealing surfaces — one on the tube and another on the fitting, angled slightly to furnish the proper stress level to keep seals uncompromised. Specific types of two-ferrule tube fittings can deliver that kind of seal integrity.

Tube Grip Strength

How strongly the fitting grips the tube is another critical element in determining whether a fitting is appropriate for high-pressure hydrogen refueling stations, as well as if it is able to stand up to the vibrations of moving vehicles.

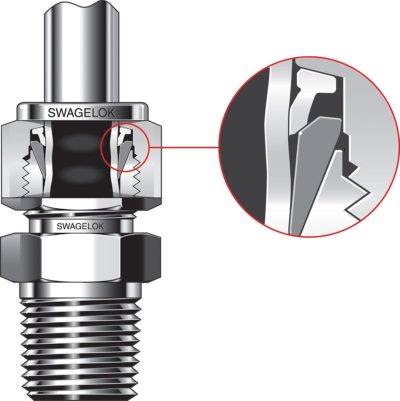

Image: Swagelok

Figure 2. The hardened front ferrule (dark gray) enables the fitting to physically bite into the tubing. The back ferrule (light gray) allows for a slight amount of movement in the fitting while maintaining grip and force.

To ensure proper grip strength, the ideal design for hydrogen fittings is a colleted mechanical grip using two ferrules (Figure 2). If the fitting has a hardened front ferrule, it can physically grip into the tubing to produce a high-pressure rating. Then, the back ferrule provides the ability for the tube to move slightly in the fitting (called “spring back”) while simultaneously keeping high levels of grip and force on the tubing. This system is vibration resistant, making it advantageous for use in vehicles and on the refueling stations, where compressors and dynamic conditions can cause significant vibration challenges.

A two-ferrule design with spring-back capability also allows fittings to withstand dramatic thermal changes, which often result in materials growing or shrinking. Particularly during refueling, hydrogen gas temperatures can range between -50°C to room temperature, which can affect the performance of conventional cone and thread fittings.

Simplified Installation

Well-designed fittings should also be easy to install, helping installation and assemblies to be more efficient. This is of particular importance to hydrogen fuel cell vehicle original equipment manufacturers (OEMs) and hydrogen infrastructure developers.

Image: Swagelok

Figure 3. For ease of assembly, a preassembled FK series fitting cartridge includes a male nut, two ferrules, and a removable plastic arbor that fit into the female port of the fitting body.

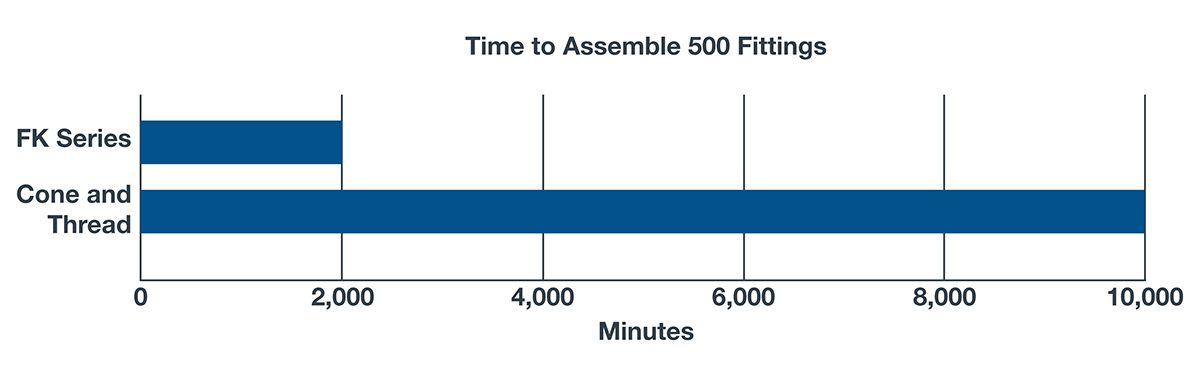

In today’s fittings market, some mechanical grip fittings come with preassembled cartridges (Figure 3), which means installers can often achieve rapid assembly using everyday tools with little chance of installation error. Conversely, installers need specialized equipment to install reliable cone and thread connections, along with specialized skills (Figure 4). In addition, installing a cone and thread fitting requires up to five times more assembly and testing time than a mechanical grip fitting like the Swagelok FK series (Figure 5). In hydrogen vehicle manufacturing, speed is important, and easier-to-install fittings save time and money as the necessary hydrogen infrastructure to serve the growing market is being built.

Image: Swagelok

Figure 4. Cone and thread fittings require operators to manually create a cone interface (shown) and threads on both ends of tubing before making connections.

Meeting the Needs of Hydrogen Systems

Though current fitting styles can be used in hydrogen fuel systems, there are only a handful on the market that are particularly designed for hydrogen applications.

Image: Swagelok

Figure 5. Installers can assemble FK series compression fittings approximately five times faster than cone and thread fittings.

To fill that gap, Swagelok’s FK series fittings have a patented design, EC 79 and EIHP certifications, and pressure ratings up to 1551 bar, specifically so they can be used in hydrogen applications. They are constructed from 316 stainless steel with a 12% minimum nickel content and have been widely used across industries and applications since their introduction, including today’s—and tomorrow’s—vehicle infrastructure.

It is essential to select and specify the proper components for important hydrogen systems to ensure the long-term viability of hydrogen transportation. Safe, reliable, and durable hydrogen vehicles and infrastructure depend on it.

About the Authors

Chuck Hayes is lead new product development engineer, and Chuck Erml is product manager at Swagelok.

For more information, download Swagelok’s Anatomy of a Hydrogen Fitting white paper.