Automation is nothing new. It has taken over key manufacturing processes for years, as well as many of the things people take for granted, like self-checkouts at the grocery store. But in the transportation realm, this idea — which was once met with apathy by many — has taken the industry by storm in the last few years.

In the Class 8 world, Daimler Truck has taken the reins and is moving at a quickening pace to reach through the different levels of autonomous driving. Recently, the OEM announced the development of a scalable autonomous truck platform suited for SAE Level 4 autonomous driving.

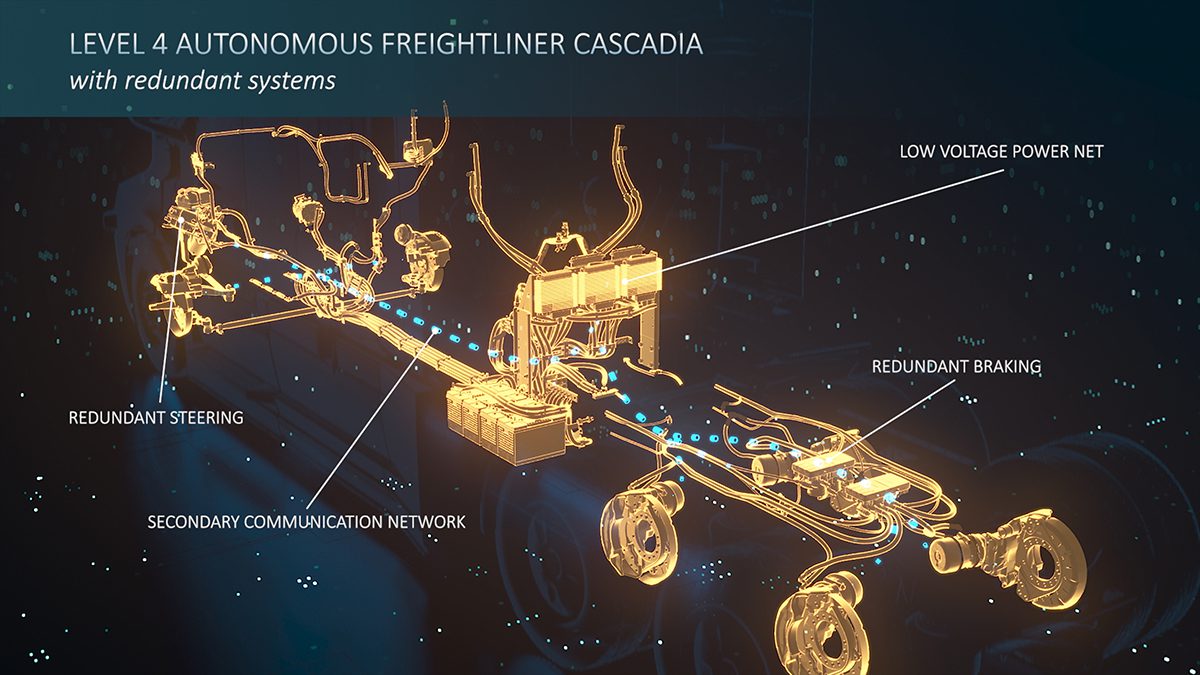

There are four crucial areas that the truck manufacturer’s redundant system oversees: braking, steering, low voltage power net, and network communications.

For a vehicle to be considered Level 4 autonomous, steering, braking, and acceleration must be controlled by the system, while the driver sits back and observes. To make its system safer and more reliable, Daimler Truck’s team of engineers added redundancy systems to its L4 truck platform. This new system has been married to the Freightliner Cascadia and includes the integration of Waymo Driver, the autonomous driving solution developed by the Google subsidiary.

There are four crucial areas that the truck manufacturer’s redundant system oversees: braking, steering, low voltage power net, and network communications. If at any point one of these primary systems encounters a fault, the vehicle monitors, assesses, and deploys a backup system to ensure the truck continues to drive safely. After receiving more than 1,500 new requirements from the Waymo team, Daimler Trucks North America’s engineers focused on these key areas.

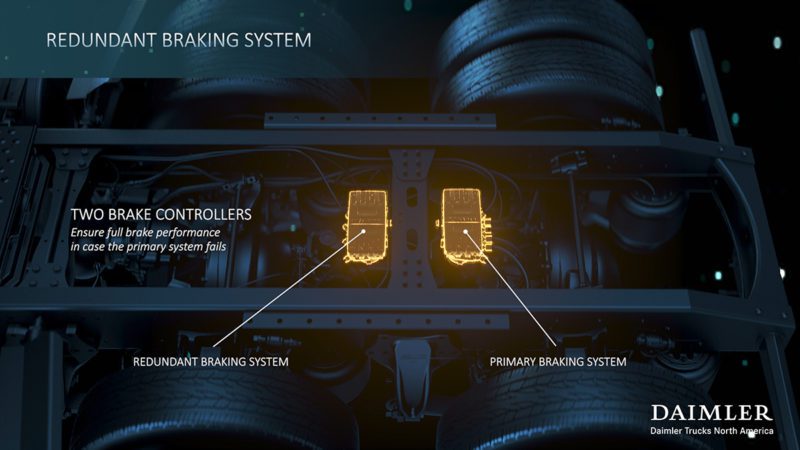

Image: DTNA

Currently, pneumatic braking systems include fail-safes to guarantee the driver’s safety if something gives out. When it comes to autonomous vehicles, engineers must be even more conscious of this possibility, with a system rather than a driver in charge of maneuvering the vehicle. An additional layer of electronic redundancy has been added to the L4 truck for the braking system — a pair of electronic control units to safeguard the brake performance so the system can safely perform what Daimler Truck calls “a minimal risk maneuver” if the primary system is not operating properly.

This is only part of the developing solution to the autonomous dilemma that OEMs and other tech solution providers are working to solve. And, for some, is probably not the answer to all the concerns they might have about autonomous Class 8 tractors motoring around the country to increase productivity and reduce the growing supply chain demands — but it is an impressive start.