Faced with the increasing need to decarbonize operations, fleets are always on the hunt for more sustainable solutions. While fuel economy and electrification will play a key role in this necessary transformation, the application of lower-carbon-footprint lubricants can also support these accelerated sustainability goals.

“Our ability to collect used oil from across the country and reprocess a waste product means that much of it can be used again and again.[1] Delivering these lower-carbon-footprint lubricants can help our business customers towards their sustainability goals with the same high quality and high performance they expect from Castrol,” said Andreas Osbar, CEO, Castrol Americas. “We believe the time is right to lead the market with an integrated more circular — and as a result, lower-carbon-footprint — offer as our business customers are searching for options to help de-carbonize their operations. This is a first-of-its kind, nationwide offer in the U.S. and we’re excited to partner with Safety-Kleen to deliver it.”

Used Oil: From Waste to a Valuable Feedstock

Re-refined base oils (RRBOs) offer an innovative opportunity to reduce lubricant carbon footprints. Base oils, usually made from crude oil, are the main ingredient in lubricants. During use, the additives in the lubricant break down, but the base oil typically remains unchanged. Using RRBOs increases circularity by turning a waste product, used oil, into new raw material, RRBO. A recent lifecycle analysis study shows that re-refined oils typically have 50% lower global warming potential during their lifetime than virgin base oils.[2] Despite these environmental benefits, only about 20% of the used oil generated in the U.S. is currently re-refined to base oils.[3]

Re-refining used oil is more than just recycling. Producing a high-quality base oil is a complex process where used oil is pre-treated to remove impurities before being refined in a similar way to refining crude oil. The result is a RRBO that exhibits very similar characteristics and appearance to a virgin base oil of the same American Petroleum Institute (API) group standard (see image).

Creating Circularity

In an effort to advance a more circular lubricants industry in the U.S., Castrol is launching the new MoreCircular program, which will not only provide lower carbon footprint lubricants[4] to its business customers but also aims to increase the amount of used oil sent to re-refining.[5] Castrol MoreCircular encompasses the entire process of collecting used oil from business customers, re-refining it, and integrating re-refined base oil into a line of premium lubricants. Partnering with industry leading environmental services company Safety-Kleen, a subsidiary of Clean Harbors, Castrol will offer used oil collection services anywhere in continental U.S.[6] The program is initially targeted at heavy-duty fleet operators and industrial manufacturers, with a product range that includes heavy-duty engine oils, as well as hydraulic fluids. When participating business customers purchase these products, they help support the development of a more circular lubricants industry.

Lower Carbon Footprint, Same High Performance

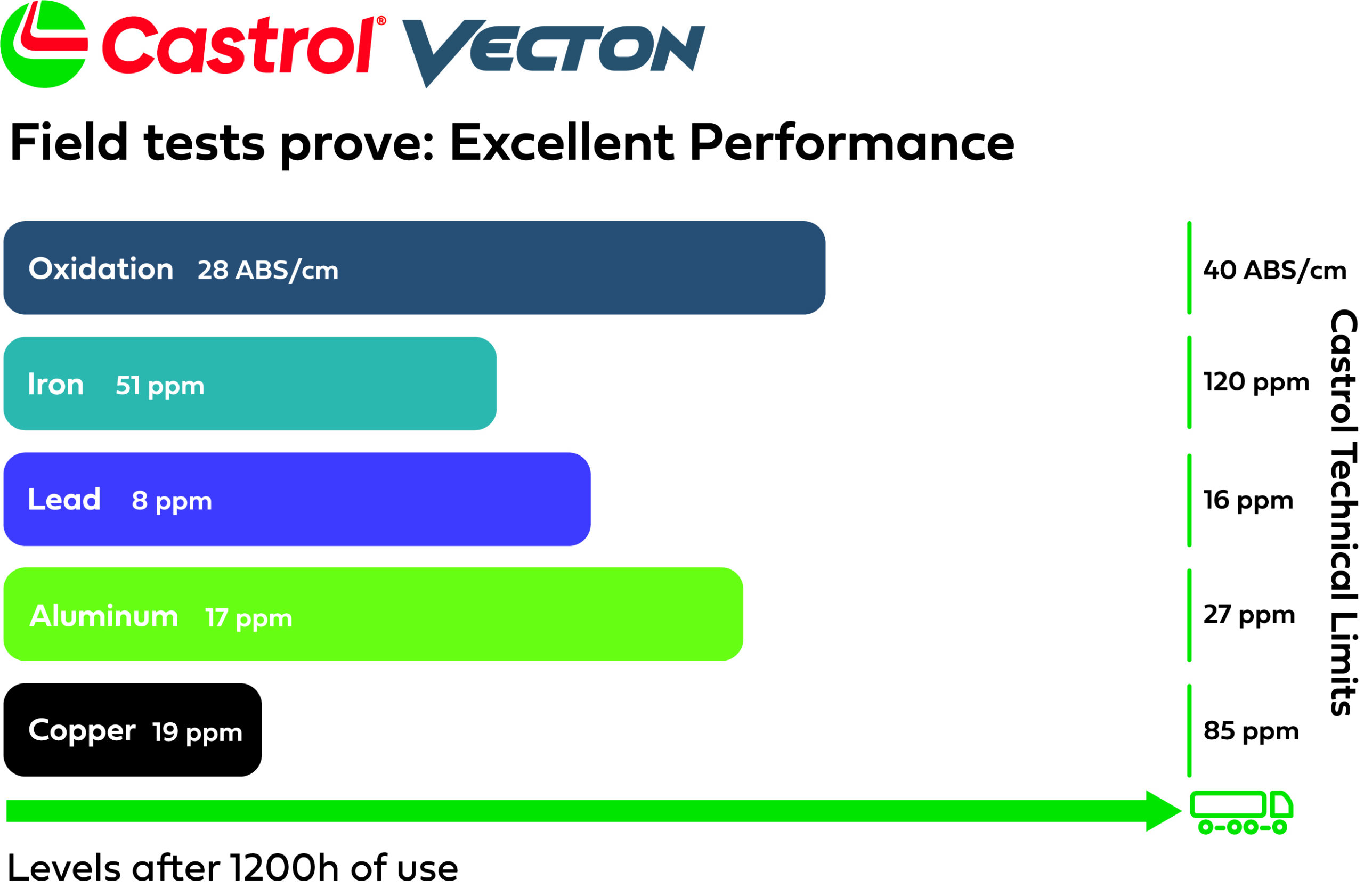

Castrol took comprehensive steps to ensure that the lubricants formulated with re-refined base oils would deliver the same high quality as the variants made using virgin base oils and continue to meet or exceed OEM and industry standards. Thanks to a significant investment in R&D, MoreCircular lubricants offer the same performance with a 20-40% lower carbon footprint compared to Castrol’s traditional products.[7] Extensive bench, engine, and field testing has demonstrated the performance of RRBO versus virgin base oil in wear, cleanliness, viscosity control, oxidation, and other performance parameters. The result: The same high-performance customers have come to expect from Castrol.

For example, the premium heavy-duty engine oil range, Castrol VECTON, proved its exceptional performance in more than 37,000 hours of field testing.[8] This comprised a fleet trial with refuse collection trucks with routes that included 900-1,200 stops each day. As you can see from the results below[9], the lubricants offered the same proven, industry-leading wear control and oxidation stability.

The key advantages of Castrol MoreCircular include:

- Lower-carbon-footprint lubricants[10]

- Proven Castrol high performance and quality

- Responsible collection from anywhere in the Continental US[11]

- One-stop-shop solution for lubricant supply and collection

To find out more about the program, find Castrol at the ACT expo at booth 831 and visit Castrol.com/MoreCircular.