High fuel costs have often been one of the main challenges fleet operators face when adopting hydrogen-electric vehicles. While advancements in technology have closed the gap on how hydrogen fuel cells compare to diesel engines in terms of range, durability, and operational uptime, infrastructure and fuel cost have remained obstacles to adoption of this zero-emission technology.

During the last few years, growing demand for clean and accessible energy has led to accelerated development of fueling infrastructure and hydrogen availability — but this is only half of the equation. The superior efficiency that hydrogen fuel cells offer fleet operators is also driving this technology forward. It is the catalyst for lowering fuel consumption and driving down the total cost of ownership of hydrogen-electric vehicles.

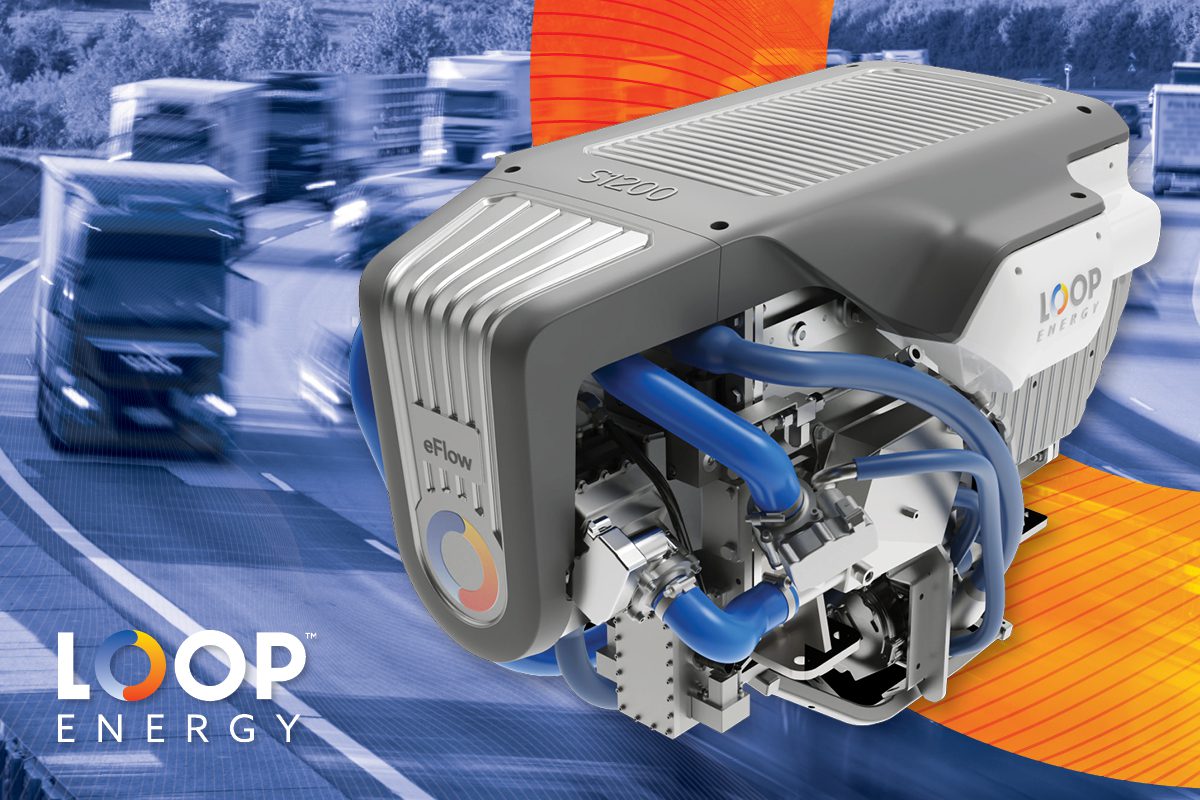

Following the launch of Loop Energy’s S1200 (120 kW) fuel cell engine, fuel cost parity with diesel is now a reality for European fleet operators. The announcement marks a milestone for Loop Energy and the global hydrogen and transport industries. The S1200’s ability to operate up to 60% efficiency across a wide cruise range makes it possible to bring the future forward in Europe. With recent commitments to hydrogen production increasing, it is only a matter of time before this is replicated across North America.

Why is this important to fleet managers? Fuel is a primary contributor to a commercial fleet’s operating costs. While the cost of hydrogen contributes to fuel affordability, it is the high efficiency of fuel cells that is closing the cost gap between hydrogen and diesel at the pump in the short-term. Here is how Loop Energy’s S1200 fuel cell engine can bring fuel cost parity forward by four to eight years.

Today, fuel consumption for an average loaded long haul diesel truck is approximately 48 litres per 100 km, and with diesel priced between $1.83 to $2.28/L in Europe, the diesel fuel cost per 100 km for the truck is $88 to $109.

Assuming a typical diesel engine efficiency of 44%, we can calculate the total energy the diesel engine produces to drive 100 km: diesel contains 10.03 kWh per litre, so the truck requires 212 kWh of energy over 100 km. Understanding that we need 212 kWh of energy to drive the same distance using a hydrogen-electric truck, and that hydrogen contains 33.33 kWh per kg, we can determine the hydrogen fuel cost for comparison.

Currently, retail-delivered hydrogen can be as low as $10 per kg, which corresponds to $90 in fuel cost over 100 km for the fully-loaded truck with 15% regenerative braking, if fitted with Loop Energy’s newest fuel cell with 60% efficiency. Here, the hydrogen fuel cost is already matching diesel fuel.

However, if the truck was fitted with a typical fuel cell with 45% efficiency, the truck’s hydrogen fuel would cost $120 for 100 km, which is not in range of diesel fuel costs. In this situation, hydrogen must decrease to $7.50/kg, or another 25% cheaper, in order to reach parity with diesel fuel cost. Yet, another $2.50 reduction in cost of hydrogen is not expected until 2026-2030. So, Loop Energy has effectively brought hydrogen-diesel fuel cost parity forward four to eight years, and its newest product’s fuel efficiency enables hydrogen to be competitive with diesel fuel costs in Europe now.

As operators and OEMs search for practical and economical solutions to electrify fleets, the impending fuel cost parity of hydrogen and diesel will position fuel cells at the front of the line and create a fuel-cost tipping point to switch from diesel to hydrogen, regulations or not.